Photo: James Bastow Hand Model: Darin White

Subtitle: The delightful Venn diagram intersections of my life here in Waterloo Region

I’m working on the big photo extravaganza FLASH while at the same time serving as artist-in-residence at the ever-awesome makerspace kwartzlab. In a meeting this week we discussed stamping hands as people enter FLASH and at the same time I was thinking I needed to arrange to be trained on the kwartzlab laser cutter. You put those two things together and –boom shaka laka (as we say at my house)—I decided to raster FLASH hand stamps for my laser training. Lasers, photography, community meetup… that’s a big bag of awesome.

FLASH thoughts for today, before a relatively small number of pics:

• Ticket holders have until this Friday Jan 16 at 7pm to get refunds on unneeded tix. No refunds after that time. Reclaim your cash + share some love with those on our waitlist.

• Notifications for the open call were all sent out yesterday morning. Please check your email/spam filter for subject line “FLASH Jury Selections” sent the evening of Jan 12 and morning of Jan 13. If you’re stuck, please email us at info@flashwr.ca

• Even if you are an open call selected photographer, you still need a ticket. I work here and bought three tickets myself.

Now back to the lasers…

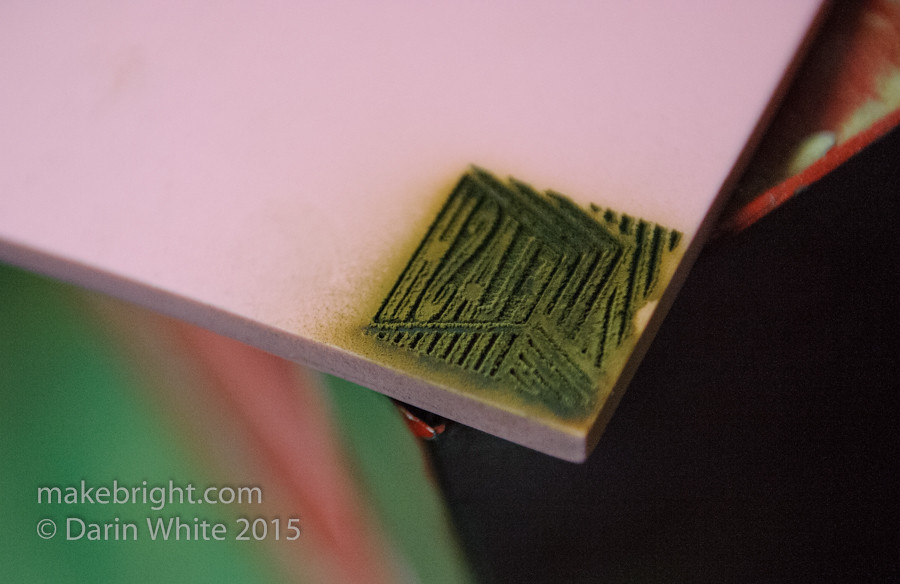

This is the business end of kwartzlab’s ginormous laser cutter. And, friends, it not only cuts; it also raster engraves! The pink material is Speedball Speedy-Carve, which is a magical rubbery sheet you can pick up locally at The Artstore of Waterloo at Caroline and William (how have I never been to this store before now?) $5.55 for a 4x6x0.25” sheet.

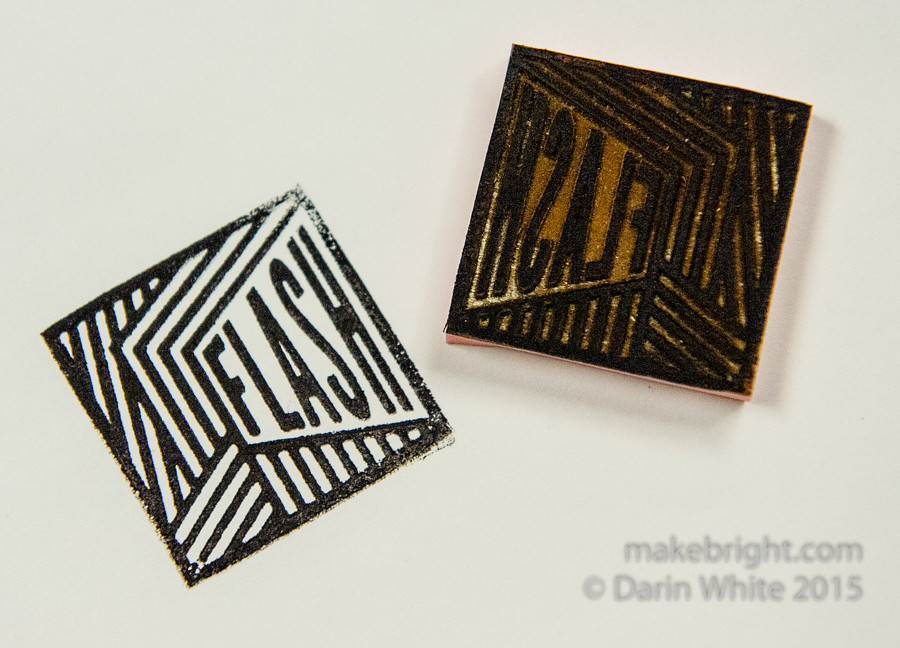

Photoshop collapsed on my laptop so Agnes kindly helped me prep the artwork for laser-stampification. And by artwork, of course I mean Jon Johnson’s awesome FLASH design. Parts that are black will be ablated (oh yes I did!) by the laser, so we had to invert the blacks and whites, and because it’s a stamp we had to horizontally mirror the design. I measured a small sample of random hands and decided 1.25” was a good handstamp size. Setting the image size down appropriately, we just needed to export a BMP file. We chose 600dpi.

There are a bunch of steps to set up the job on the laser. Downloading the job. Homing the axes. Focusing the laser for the material. Setting speed, power, and step-over. Happily, Agnes had already worked with Speedy-Carve and had recorded the optimal parameters.

Glorious result! You need to wash out the burnt rubber powder with soap and water and ideally a toothbrush. Rastering with the laser, for the uninitiated, is where the cutting head scans a horizontal line, burning away where necessary, and then advances vertically a very tiny amount and repeats the horizontal scanning in the other direction. Repeating this over the inch and a quarter reveals the design. The alternate to rastering would be vector cutting (think “lines”) in which case we would feed in a DXF file instead of a bitmap.

Clean. Wasn’t sure if the engraving was deep enough to give a clean stamp given the squishiness of hands. Only one way to find out.

Cut with a hobby knife. Like butter. Aaaand, for crying out loud, I didn’t pick up a stamp pad. Agnes improvised with some block printing ink.

Photo: James Bastow Hand Model: Darin White

Sweet success.

Agnes insisted we try it on paper but I couldn’t stop looking at my hand. Looks like all we need now are some wooden handles and double-sided tape…

Oh yeah, and an ink pad.

As usual, massive thanks to the queen and king of making, kwartzlabbers Agnes Niewiadomski and James Bastow. Aga had the stamp knowledge and James had the laser knowledge. There is an unbelievable concentration of maker-fu in this dynamic duo. Really.

Photo: James Bastow Hand Model: Darin White

Say hello when you see me at the show (rhyme!)

DW