For those not following along, I’m helping revive some long-unused CNC machine tools at our awesome local high school, Sir John A. MacDonald in Waterloo, Ontario Canada…

After a lot of reverse-engineering of the CNC control box at home and some substantial design/soldering/troubleshooting/bench testing, I got back into the school today with tech teacher Dean Henderson to try my adapter electronics on the actual mill and lathe. Here’s a test run video of the new and super-easy web-based CAD/CAM/cut tool from Easel.com. The goal here is to turn students on to the power of rapid prototyping, so simple tools and fast workflow is key. You do up your design in Easel and generate your toolpath and just hit “Carve”. That sends a stream of motion commands (g-code) down the USB serial port to an Arduino I’ve configured with the open motion control tool GRBL (which drives a lot of 3D printers and mills in the world). GRBL buffers those commands, does some rudimentary optimization, and feeds out step/direction signals to the motor drivers.

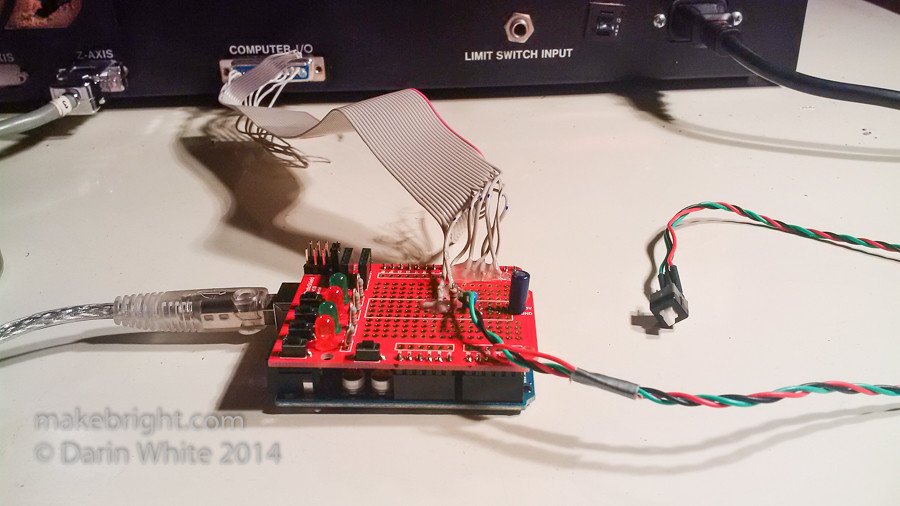

In many applications, the motor drivers are built right on to the Arduino in the form of an add-on shield. In our case at SJAM, we already have perfectly good motor drivers in the TORCAM control box I reversed engineered. So I interfaced the Arduino with the 25-pin Dsub connector on the CNC control box. And it works.

Update 2015-07-21: looks like a burst of interest on this post, so here is some of the background work I did to get to this point.

Some details and tweaking still to be done, but I am delighted with how this came together. Now we can make some stuff… in Waterloo.

DW

Niiiiiiiice! See I TOLD you to stop mucking about with that olde parallel port 🙂

That’s really cool.

Nice work DW! I can’t even fix my hair dryer…what an awesome thing to bring back to life! Gotta add some lightning bolts and Frankenstein music in that video! Muahahaha Cool to see you got Easel working with something so old. I’m getting my training on our beastly CNC router next week…so watch out for more crazy BIG projects to come!

Awesome!

Hello Darin,

That Torcam Mill sure looks like it was an interesting project. I have acquired a Torcam CNC Lathe with no electronics and I was wondering if you knew the history behind Torcam or where these machines came from? I have googled every keyword I can think of and your cnc mill is all that I can really find.

Hi Will,

Thanks for your question on my TORCAM blog post on makebright.

I know very little about the origins of the company. From one of the circuit boards in the motor driver box I got the name “TOR Computerized Systems Inc” which turned up the following link with address in the Greater Toronto Area and the principals of the company:

https://www.ic.gc.ca/app/scr/cc/CorporationsCanada/fdrlCrpDtls.html?corpId=1984764

Looks like the company was renamed/rebranded Studica. Here’s a link showing Frank Nanfara:

https://www.studica.com/blog/studica-celebrates-30-years-of-business

Presumably the TORCAM CNC rigs landed in a lot of Ontario high schools. I’ve heard from a teacher in Scarborough with a mill and a student in Walkerton who has some TORCAM gear. Everyone seems to be searching for data on these machines. Not surprising given that they are so mechanically robust. Seems a shame to scrap them.

Good luck getting your lathe up and running.

DW